10 Sep Complete Guide to Choosing Flooring Underlay

You will always need underlay for floating floors. However, not all underlay are created equal – but that’s ok, this article will explain to you how underlay works, and how to determine which underlay you need.

Soundproofing your home is a luxury, but more often a necessity. This is especially true if you live in apartments and townhouses which enforce strict body corporate/strata policies regarding noise levels.

Installing flooring without abiding by the strata requirements can result in very very expensive repercussions – you’ll be forced to rip up all the floors and install the right underlay.

What is flooring underlay used for?

Flooring noise reduction is primarily achieved through the use of an acoustic underlay. Installers will need to lay rolls or sheets of underlayment over the subfloor before installing floating floorboards on top. Think of underlay as a layer of foam or rubber material that cushions any impacts and blocks loud noises

Acoustic engineers determine the effectiveness of flooring underlay by testing the underlay in-situ against noises. Although underlays are primarily designed for noise reduction, they can also function in a wide variety of applications:

- Impact Noise – Sounds caused by direct footfalls, thumping and dragging furniture.

- Ambient Transmission – Sound from televisions, chatter and other indirect noise in the air.

- Moisture Protection – Can act as a moisture barrier to protect your wood floors.

- Insulation – Can provide thermal insulation, keeping your summers cooler and winters warmer.

- Comfort – Can increase the comfort underfoot by making each step feel less hollow.

- Subfloor Levelling – Thicker underlayment can be used to help level uneven subfloors in some cases. (not always suitable for this purpose)

There are two main categories of hard floor underlay; namely foam underlay and rubber underlay. Foam is by far the more affordable type of underlay because they are cheaper to manufacture and much lighter to transport, however tend to have lower performance in both comfort and noise reduction compared to rubber underlay. Furthermore, foam underlay actually flattens over time because it does not have the same density and resilience of rubber.

Types Of Foam Underlay

Silver EPE foam underlay is by far the most commonly used option as it is the most affordable underlay. Whilst it offers no significant ‘acoustic’ reduction, the waterproof film and 2mm foam composition function to protect your floors from moisture and movement.

Gold EPE foam underlay is 3mm thick, offering a softer and comfier feel underfoot than the general silver option. This is considered non-acoustic underlay as they are not designed to reduce noise transmission.

The ‘EveQuiet Green’ acoustic underlay is the most common option for noise reduction. Offering 5 star acoustic protection, they serve very well in most units and apartments.

You can explore and shop our full range of foam underlay options.

Types of Rubber Underlay

Rubber underlay comes in many formats and thicknesses to suit your requirements. The most commonly used rubber underlays are the 3mm and 5mm options as they easily achieve a 5 star performance and are specified by strata management in Sydney. On top of noise reduction, rubber underlay also absorbs vibrations and performs much longer than foam underlay which can flatten over time.

Wavy rubber underlay takes noise reduction to the next level and can achieve a whopping 6 star acoustic performance in some conditions. Their wavy surface is designed to capture as much impact noise as possible, however is more costly to manufacture than your standard flat rubber underlay. Wavy underlay is available in 5mm and 10mm thickness.

The newest and most innovative rubber underlay combines the best properties of foam and rubber. Our composite rubber underlay achieves a slightly better performance than standard rubber of the same thickness, and yet costs less to manufacture. Furthermore, they are lighter and easier to transport or install.

Feel free to explore and shop our full rubber underlay range for hard floors.

Cost of Underlayment

The real question is whether or not the cost of purchasing underlay will significantly impact your flooring project. The price per square metre generally increases with the number of AAAC Star Ratings an underlayment has. However, this is not always the case. The prices of underlay in Sydney as of 2024 are provided below:

- General Foam Underlay 2mm: $2 – $5 per square metre

- 4 star Acoustic Underlay: $5 – $7 per square metre

- 5 star Acoustic Underlay: $7 – $30 per square metre

- 6 star Acoustic Underlay: $50 – $100 per square metre

The most expensive flooring underlay options can range up to $100 per square metre, however they are incredibly uncommon requirements. The vast majority of flooring underlay requirements will not exceed $15 per square metre, so rest assured it probably won’t eat into your bank.

How to determine your underlay requirements

Now that we understand how floor soundproofing works, let’s find out how to determine whether or not you will need flooring underlay. How do you know if you need underlay and how do you know which you need?

- Are you living in an apartment? If so, there is a 99% chance you will need some form of underlayment for your flooring.

- You will need to contact your strata by email regarding acoustic underlayment for flooring if it is required. They will likely provide you with information regarding a required underlay thickness, an AAAC rating or a specific type of underlay

We have an entire guide to getting strata approval for flooring renovations. I recommend reading this if you want to get approval quickly.

Floating Floor Underlay

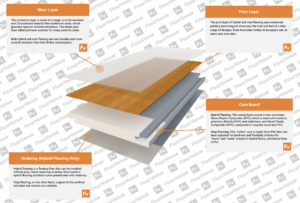

Only floating floors require an underlay. Floating floors are a group of flooring types that do not require glue or nails during installation, and are instead ‘floated’ on top of the subfloor. To put it simply, we do not directly nail or glue them into the subfloor. Floating floors include laminate flooring, bamboo flooring, hybrid flooring and engineered timber flooring.

If you are looking to install solid timber into your floors with direct-stick to the subfloor, underlay will not be required. This scenario can arise if you do a glue-down installation of solid timber into your apartment since the strata does not allow noisy nail banging.

Hybrid Floors and Pre-attached Underlayment

Most (not all) hybrid floors come with pre-attached underlay which have AAAC Rating certifications. This means you won’t need to add additional underlay if it already meets strata requirements.

For example, FloorVenue stocks Marvel SPC Hybrid flooring which has a 6 star acoustic underlay pre-attached. Marvel hybrid floors can virtually be installed anywhere since it has the highest acoustic certification without the need for additional underlay. (Unless the strata demand a certain underlay thickness regardless of AAAC rating)

Technical Flooring Underlay Details

Noise reduction can be simplified into AAAC Star Ratings, from 1 star at the lowest up to 6 stars which is the highest. Flooring acoustic standards are determined by the National Construction Code (Previously known as Building Codes Australia) and your strata bylaws.

If acoustic underlay is required, it will be at least 4 stars or above. Most apartments, units and townhouses require a 5 star rating. Some more stringent areas will demand 6 stars or a certain thickness.

AAAC star ratings are essentially simplified abbreviations for the level of decibel reduction from noise. This technical measurement of underlay performance is measured in LnT,w.

LnT,w – LnTw is the weighted, standardised impact sound pressure level of a floor assembly. The lower the LnTw value, the better the acoustic performance. This is measured in decibels (dB).

- 2 Star acoustic rating – LnT,w < 65 dB

- 3 Star acoustic rating – LnT,w < 55 dB

- 4 Star acoustic rating – LnT,w < 50 dB

- 5 Star acoustic rating – LnT,w < 45 dB

- 6 Star acoustic rating – LnT,w < 40 dB

Testing Conditions:

The AAAC rating of underlay is tested on-site with various types of flooring, the specific underlayment, concrete subfloor (150mm – 200mm) and a ceiling cavity to replicate a real-world scenario. Noise insulation is measured by direct impact sources as well as ambient noise from 50 – 10000 hertz.

The underlayment requirements depend on the building classification which comes in 10 classes. These adhere to the National Construction Code (NCC).

Conclusion – What Are Your Next Steps?

Hopefully, this guide was about to assist you in determining whether or not underlay will be required. If you have any questions, queries, comments or complaints – don’t hesitate to reach out. FloorVenue stocks and supplies a multitude of underlay and our friendly consultants have extensive product knowledge. We’ll definitely be able to help you make the right decisions.