14 Aug Ultimate Guide to Choosing Timber Flooring [In Australia]

So you’re looking for a new floor to install in your home or office, and you just can’t look away from the natural warmth and beauty of timber flooring. So what’s next?

We get it — selecting and installing your new floor can be confusing because of all of the research and choices that you’ll need to figure out. But it doesn’t have to be difficult.

In this article, we’ll simplify the process, guiding you step-by-step through choosing a timber floor. By the end, you should be able to decide on the timber floor that looks great and suits you best.

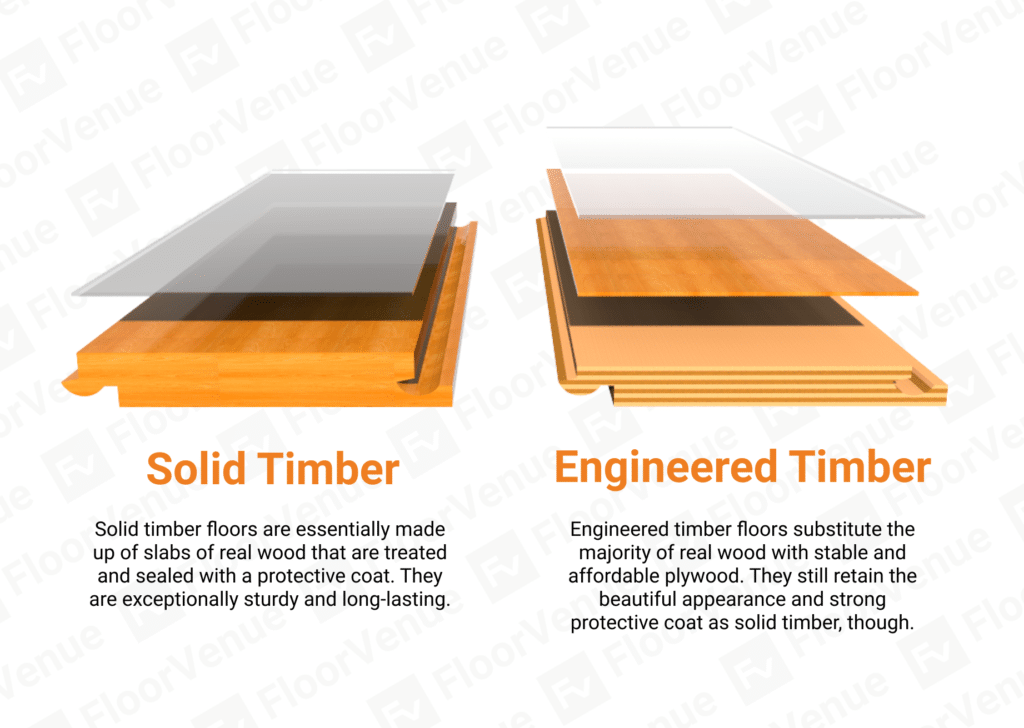

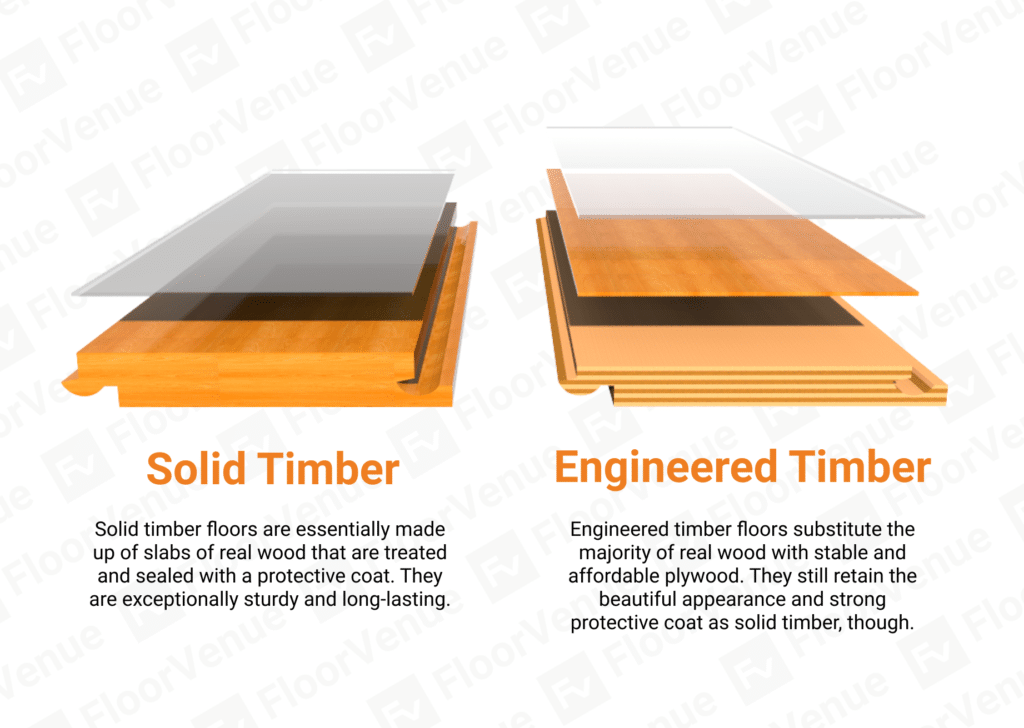

Solid Timber vs Engineered Timber Floors

The first step in your flooring journey is to choose between solid timber or engineered timber floors.

Solid timber flooring is constructed entirely from real wood sourced from slow-growing trees. Meanwhile, engineered timber flooring is made with a top layer of real hardwood combined with plywood layers beneath.

So, what does this mean for you? In short, solid timber floors offer a longer lifespan since they can be sanded and refinished many more times. Engineered timber floors, on the other hand, are generally more affordable and provide greater stability, meaning they are less prone to expanding or contracting with changes in temperature and humidity.

Once you’ve chosen your flooring type, the next step is to decide on the key features of your floor — such as whether to go with prefinished or raw timber, the width of your floorboards, and the type of surface coating. These considerations differ slightly between solid timber and engineered timber, which we’ve outlined in detail below.

For Solid Timber Flooring

1) Prefinished or Raw?

Prefinished timber flooring is coated (stained and sealed) in the factory, ensuring the best possible finish. It’s easier, quicker, and cheaper to install. Prefinished floors also don’t require an acclimatisation period before installation.

Raw timber flooring arrives uncoated and unfinished. After installation, it needs to be sanded and coated, adding time and cost. However, raw timber offers flexibility in choosing stain (light or dark) and finish (glossy, matte, etc.), and can achieve a more uniform surface when installed professionally.

Both prefinished and raw timber floors can be sanded multiple times, depending on thickness and the depth of previous sanding, which allows you to refresh your floors over time.

2) Choose Species and Grade

The timber species you choose will affect your floor’s durability, cost, colour, and overall look. After choosing a species, you’ll also need to select a grade of timber, which is defined by the natural features in the wood:

- Select Grade — minimal features or discolouration, generally higher cost.

- Medium / Standard Grade — moderate features and discolouration.

- High Feature Grade — lots of features and discolouration, lowest cost.

3) Plank Size (Thickness & Width)

Narrow floorboards (80–95mm) suit smaller rooms, creating a sense of space. Wide floorboards (100–130mm) look contemporary and highlight grain patterns but are costlier and more prone to warping, making engineered timber a safer option in humid areas.

Thickness ranges from 12–22mm. Thicker floors feel sturdier and can be sanded more often but cost more. To minimise issues like cupping or buckling, FloorVenue installers follow Australian Standard AS 2796 for acclimatisation, board spacing, and movement allowances.

4) Choose Surface Finish (and Coatings if Raw Timber)

Prefinished Timber Flooring

Factory-coated prefinished floors offer fewer finish options:

- Gloss — shiny, reflective, shows dust/scratches more easily.

- Semi Gloss — moderate shine, scratches less visible.

- Matte — natural look, highlights timber grain, hides dust/scratches.

Raw Timber Flooring

Raw timber allows more customisation with coatings and finishes.

Coating Options

- Oil-Based Polyurethane — moisture-resistant, durable, may yellow, slow-drying, VOC emissions.

- Water-Based Polyurethane — low VOCs/odour, easy cleanup, less durable, more scratch-prone.

- Modified Oil — blend of oil and polyurethane, durable, slower to dry, may release VOCs.

Always check manufacturer instructions for coating application.

Surface Finish

- Gloss — shiny, enhances natural light, shows dust/scratches.

- Semi Gloss — moderate shine, hides dust/scratches better.

- Matte — minimal shine, natural look, hides scratches/dust effectively.

For Engineered Timber Flooring

1) Prefinished Only

Most engineered timber floors come prefinished, so no extra sealing or treatment is required after installation.

2) Choose Timber (Aussie, Overseas and Oak)

Australia offers quality hardwoods such as blackbutt and spotted gum. Overseas timbers like Kempas, Walnut, and Merbau are also popular. Recently, oak flooring from Europe and America has grown in demand thanks to its tight grain and unique patterns.

3) Choose Species and Grade

Choose a base timber species (e.g. Jarrah, Spotted Gum, Ironbark). If opting for oak, select a factory pre-stained colour scheme. Then, choose a grade (A–D), with A having the least natural features and D having the most.

4) Plank Size (Thickness & Width)

Engineered floors let you customise three main measures:

- Total Thickness — 12–21mm overall, thicker feels more solid.

- Timber Veneer Thickness — 0.6–6mm top layer; thicker allows more re-sanding.

- Width — 90–240mm, wide boards highlight wood grain, thin boards suit smaller spaces.

Engineered floors are more stable in humidity changes, allowing for larger widths. Generally, thicker and wider boards cost more.

5) Choose Surface

Two main surface styles are available:

- Smooth — gloss, semi-gloss, or matte. Gloss brightens spaces but shows scratches.

- Hand-crafted / Hand-scraped (Matte) — textured finish for a realistic timber feel.

How Timber Flooring Installations Work

Both solid and engineered timber floors can be glued and nailed to a subfloor, but engineered timber can also be floated. A floating floor is installed over an existing floor, making it quick and renter-friendly, though it can sound more hollow and requires underlayment.

According to Australian Standard AS 1884, subfloors must not exceed 4mm variance over 2 metres for floating or glued timber installations. Compliance prevents hollow sounds, uneven wear, or shifting over time.

Explore Your Timber Flooring Colours and Options

Congratulations! At this point, you’ve just completed the hardest part of specifying your new floor. What next? Check out our range of solid timber and engineered timber flooring colours and options to get the design you’ve been waiting for.

At FloorVenue, we specialise in supplying and installing timber flooring and would love to give you a free no-obligation quote — get in touch with us, and we’ll get back to you!