14 Aug The Ultimate Guide to Engineered Timber Flooring

At FloorVenue, we separate engineered flooring into Engineered Australian Hardwood and Engineered Oak Timber Flooring to help our customers find their favourite floor. Whilst both are a layer of timber bonded to a coreboard, some people love the Australian timber look and should explore the Engineered Australian Hardwood page, whilst others love the European Oak and American Oak timber look and should explore the Engineered Oak Timber Flooring page.

Both are great flooring options – oak engineered floors have more colour options, but Australian timbers are slightly more durable and very popular in Aussie homes. Both are very stylish and the choice is yours to make!

What is engineered timber flooring?

Engineered timber flooring offers the natural beauty and durability of traditional hardwood with added benefits such as improved water resistance and greater stability in varying climates. Unlike synthetic options such as laminate or hybrid, engineered timber incorporates real hardwood in its construction, giving it an authentic look and feel.

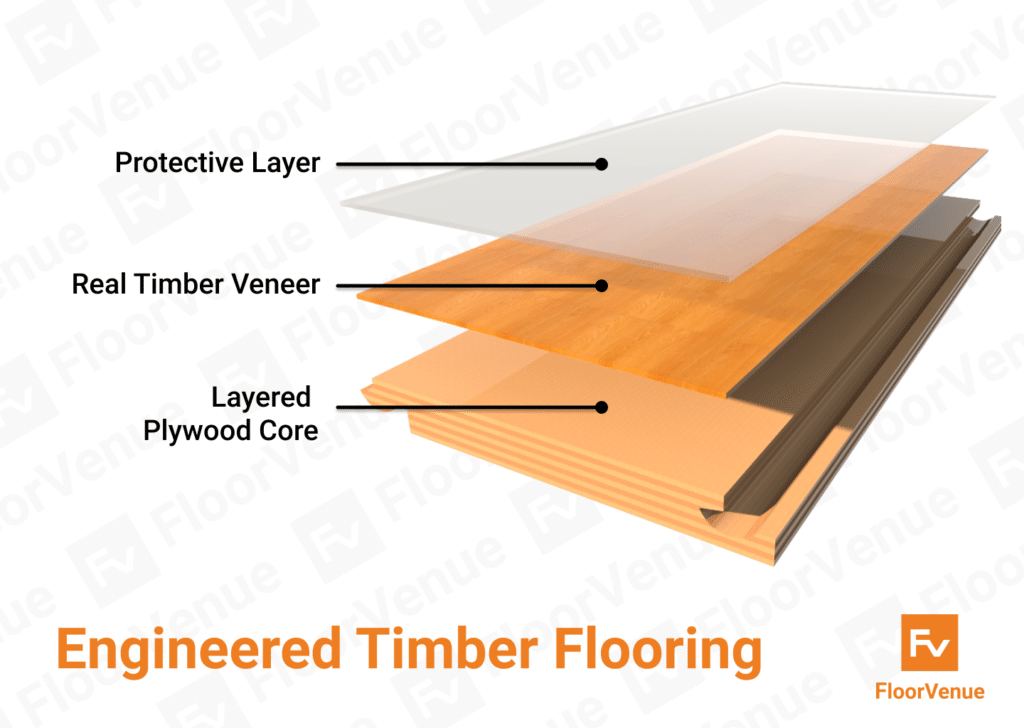

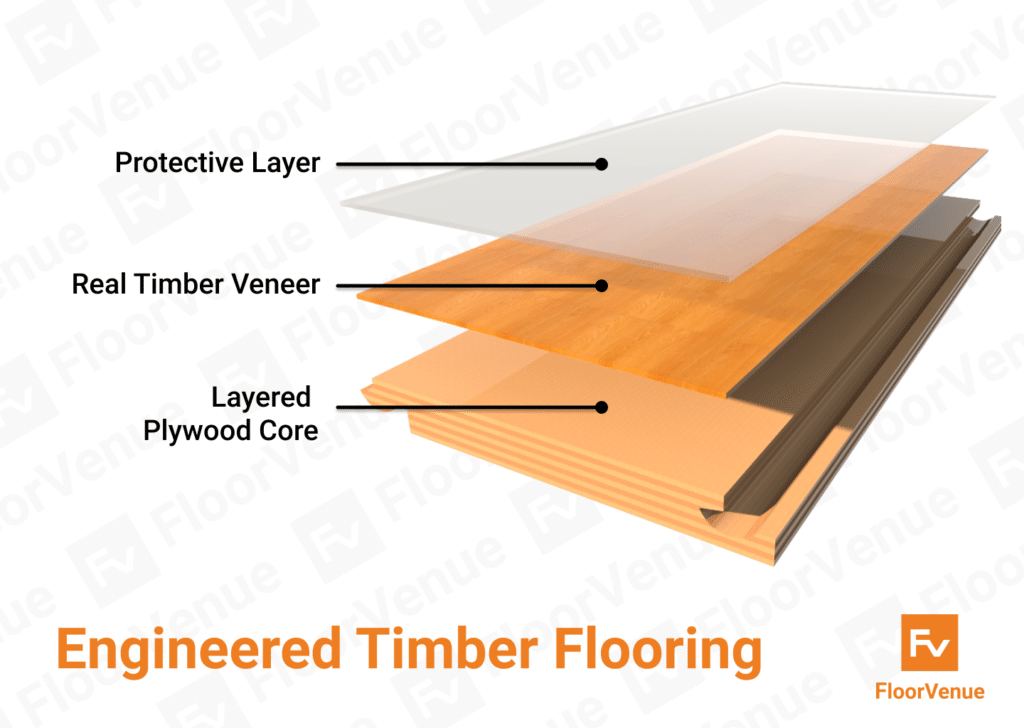

Each plank is built from multiple layers, with a top veneer of genuine oak or hardwood bonded to a base of sturdy plywood. This layered design not only makes engineered timber more cost-effective than solid timber but also reduces expansion and contraction caused by changes in humidity and temperature — ensuring a more stable and long-lasting floor.

Most engineered timber flooring products come prefinished, meaning they are factory-coated with protective layers before installation. This enhances durability and scratch resistance while also reducing installation time and costs, as there’s no need for sanding or finishing after laying the floor.

Some modern engineered timber floors are even designed to be water-resistant. For example, FloorVenue’s HydroPro Water-Resistant Aussie Timbers allow engineered timber to be installed in kitchens and laundries — areas that traditionally wouldn’t suit natural timber.

To ensure long-term performance in these wet areas, installation should also comply with Australian Standard 3740 (Waterproofing of domestic wet areas), which sets guidelines for moisture protection and waterproofing.

What is the difference between solid timber flooring and engineered timber flooring?

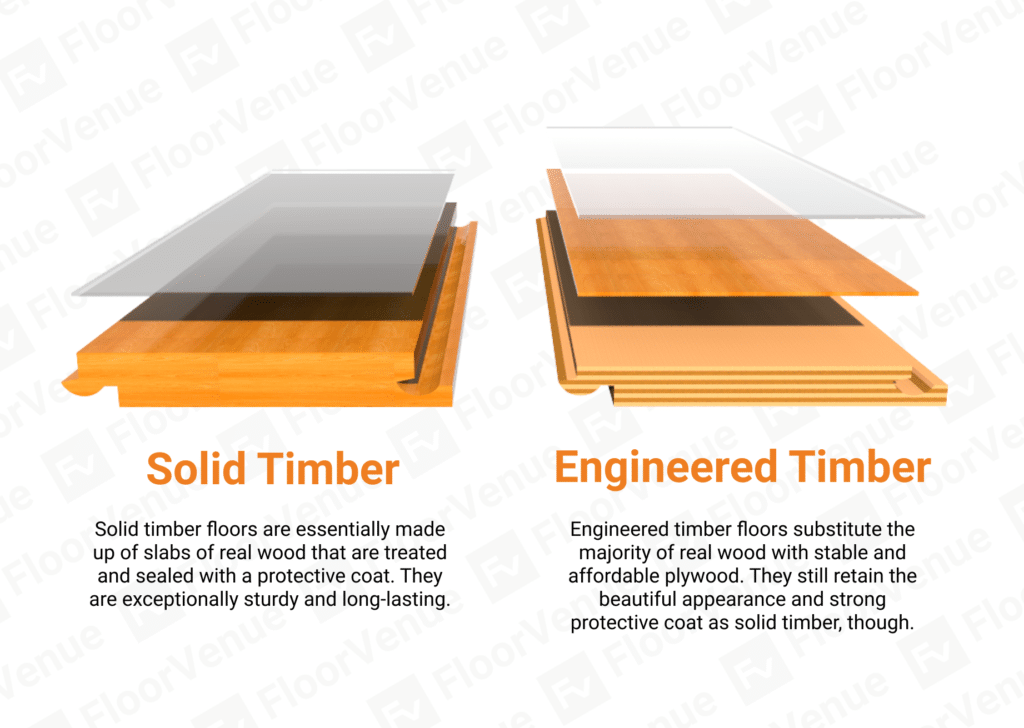

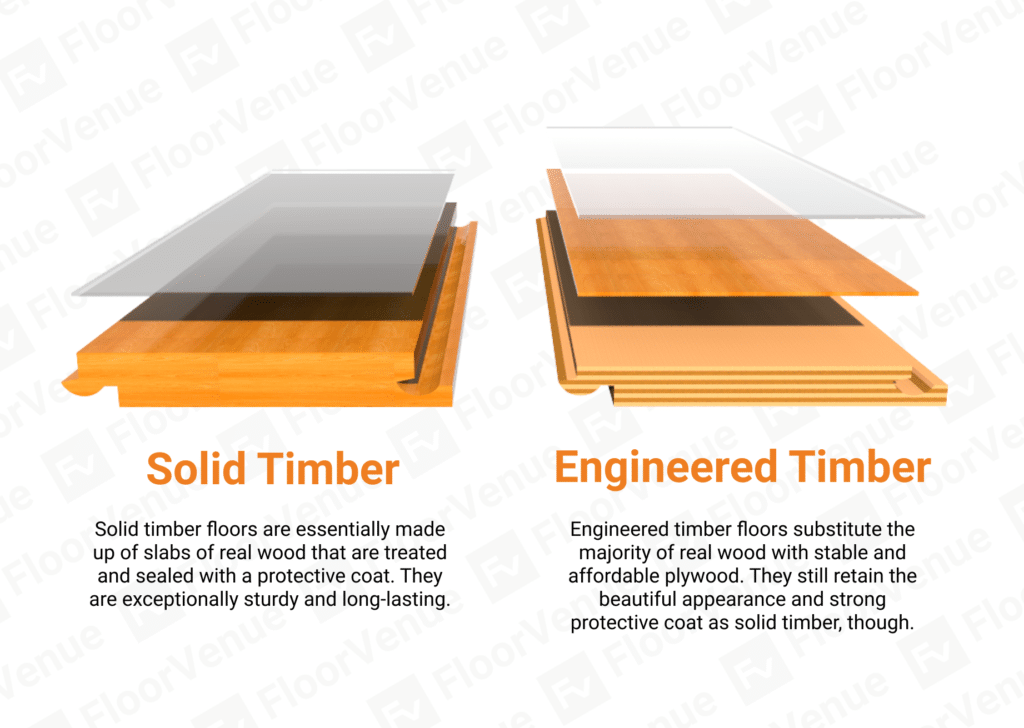

Both solid timber flooring and engineered timber flooring give you the look and feel of actual hardwood timber on the surface, but they’re different in how they’ve been manufactured.

-

Solid timber flooring is made from a single piece of wood throughout, milled and dressed into sturdy floorboards.

-

Engineered timber flooring features a thinner top layer of real hardwood bonded to a stable plywood base, which improves rigidity and reduces movement from changes in humidity or temperature.

Because solid timber requires more hardwood, it is generally more expensive. Its main advantage, however, is longevity — with proper care, it can last for generations. Both flooring types can be sanded and refinished to restore their surface, but solid timber can typically undergo this process many more times than engineered flooring, giving it a longer potential lifespan.

How to lay engineered timber flooring?

One of the key advantages of engineered timber flooring is the flexibility it offers when it comes to installation.

Floating Installation

The most common method is to install engineered timber as a floating floor, where planks are laid over the existing surface (the subfloor) using a click-lock system. This method is fast, affordable, and especially popular in apartments and unit blocks, as it can be easily installed or removed. However, floating floors require a flat subfloor and cannot be laid over carpet. They may also sound slightly hollow underfoot, but this is easily resolved by adding an acoustic underlay, which improves both comfort and sound insulation.

Direct Fix Installation

Alternatively, engineered timber can be fixed directly to the subfloor using staples, glue, or nails. This method creates a more permanent installation with a premium feel underfoot and is often required for floorboards with a traditional tongue-and-groove system.

To ensure stability and longevity, our expert installers follow Australian Standard 1884 (Resilient flooring installation), which sets subfloor preparation tolerances at no more than 4mm over 2 metres.

If you’d prefer to have the peace of mind of leaving flooring installation to the professionals, reach out for a free, no-obligation quote!

What are the advantages of engineered wood flooring?

1) It’s easy and quick to install

As we’ve discussed above, engineered wood flooring can be installed as a floating floor. This drastically cuts down the cost and time of installation, although you are still required to put in a type of underlay to soften any noises from the floor.

Most engineered timber flooring products come prefinished with a protective sealant at the factory. This means that you don’t need to deal with the hassle of surfacing the floor after installation, unlike what we call ‘raw’ flooring timber.

2) It’s relatively affordable

Engineered timber floors give you the same premium surface as solid timber, but at a fraction of the cost. If getting the look and feel of real hardwood is important to you, engineered timber is a serious contender for the money.

3) It’s durable

Engineered floors have superior durability and scratch-resistance due to their use of hardwood timber and a strong protective finish. They can last for decades when properly maintained, and can look the part too – if your floor timber starts to get worn, you can simply sand it to reveal a fresh surface underneath. Thicker engineered timber floors can usually be re-sanded 2 or 3 times over their life, with about 1mm of thickness used per sand.

4) It’s stable during weather changes

As the fibres in wood can retain moisture, changes in humidity can cause expansion and contraction in any floor that uses these natural materials. Engineered floors do this to a lesser extent, however, due to their use of stable plywood underneath.

What does this mean for you? Well:

-

- During extreme weather, engineered timber has a lower likelihood of buckling or creaking.

- You can leave smaller expansion gaps between floorboards during installation in your home.

- You can find engineered hardwood flooring products with wider floorboards that really bring out the natural wood grain and texture.

5) It’s versatile

The natural beauty of wood has been well-regarded for centuries, and engineered timber makes it more accessible for you to embrace the elegance of hardwood flooring in your home. Not only are they more affordable, but they’re even suitable for renters when installed as a floating floor!

Engineered timber floors come in a diverse range of species, so you can choose the style which suits you. For example, you could opt for the warm sunset-like hues of jarrah, or the wide colour variation of spotted gum. The possibilities are endless!

Floating floor comparison: Engineered timber flooring vs laminate flooring vs hybrid flooring?

If you’re looking to install a floating floor, you’re primarily confined to the range of engineered timber, laminate and hybrid floors. So what’s the difference among them?

Engineered timber flooring is veneer timber flooring with a top layer of real timber and multiple layers of plywood underneath; Laminate and hybrid flooring are flooring options that essentially use a photograph of timber that’s printed and layered between a hard protective coat and a solid substrate. The primary difference between the two is that the base substrate is composed of HDF for laminate and SPC/WPC for hybrid. As such, hybrid floors provide increased water-resistance compared to laminate floors.

As synthetic products, laminate and (to a lesser extent) hybrid floors are more affordable compared to engineered timber. They both feature a wider range of styles, even those that don’t look like wood – in fact, FloorVenue stocks a range of more than 100 styles of laminate flooring products alone!

However, laminate and hybrid floors can’t really capture the unique character of wood, and they just don’t look and feel the same when compared side-by-side to the real thing. As such, engineered timber products outshine laminate and hybrid when it comes to longevity and durability, albeit at a higher initial cost.